Fluid Film Vs. Fluid Film Black: An In-Depth Comparative Discussion

Rust is one of the worst enemies of automobiles and other metallic surfaces. Over the years, the rust sits on the metal surface and causes it to erode and deteriorate. Also, the rust will damage the beautiful texture of the cars, SUVs, and any metal surface. Thankfully, you can keep the rust at bay with the fluid film coating on it.

Fluid film comes in traditional and black versions. So, before choosing one, you must know the difference between traditional fluid film vs. fluid film black. Also, you should thoroughly understand their applications and use guidelines.

Traditional fluid film is available in tan or clear coating, and the black one comes with a black tint with an added layer. The black fluid film is best for use in bare metals, especially anything underneath your vehicle. On the other side, the traditional transparent fluid film works best on the beautiful surface of your car to give it maximum rust and corrosion protection.

What Is Fluid Film?

We understand that most people have a curiosity to know what Fluid Film is in reality. Also, what are the differences between a fluid film and a regular rust protector?

Fluid Film is a versatile corrosion prevention and lubrication product. Primarily, manufacturers use lanolin to formulate the film. The lanolin is a natural substance derived from sheep’s wool. It provides a protective barrier against rust, corrosion, and moisture. Henceforth, it is ideal for many applications, from automotive to industrial rust protection.

Also, unlike regular rust protectors and paints, it’s free of solvent. It’s made of natural lanolin, which sticks to the metal surface for a longer period. It doesn’t evaporate like the solvent to expose the metal surface to air and contamination after a few months.

Fluid Film vs. Fluid Film Black: The Differences and Similarities

Fluid film was previously available only in the traditional clear or tan formation. Of late, it is also available in the black version, and it has caught the attention of car and SUV owners. So, what makes them distinctive, and also, are there any similarities?

Color:

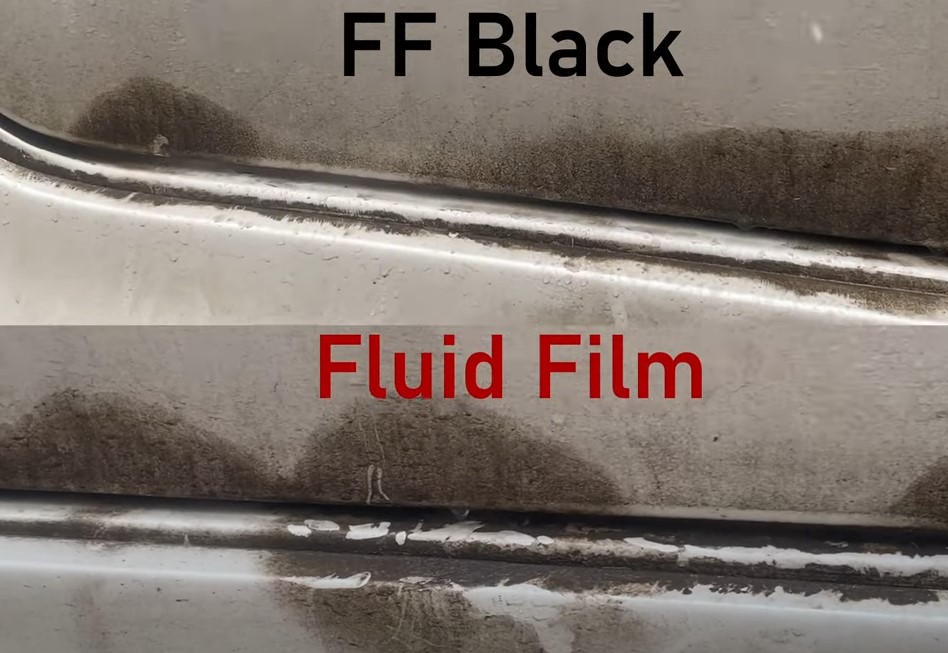

The most noticeable difference between Fluid Film and Fluid Film Black is their color. Traditional Fluid Film is typically light amber or straw-colored. It is more like a transparent or tan finish. On the other hand, Fluid Film Black, as the name suggests, is in black.

As you apply the black fluid film, it creates a thick black coating on the surface. So, it gets harder for pollutants and corrosion to penetrate the layer to damage the metal underneath it.

The color difference may influence your choice, too. It will have different impacts on the aesthetic or visibility after application. The regular fluid film is preferential for automobile and metal surfaces. On the other hand, the black version is more suitable for bare metallic versions that you need to protect. Fluid Read this article: Film Black Vs Red

Pricing

Fluid Film Black is often priced slightly higher than standard Fluid Film. The price difference is due to its specialized formulation. No doubt, both products offer excellent corrosion protection. So, it’s your budget that may play a role in your decision-making process.

For instance, the regular Fluid Film 11.75oz Aerosol is priced at $9.99. The Fluid Film Black 11.75 oz. Aerosol, on the other hand, is priced at $11.99 to $12.99. As you see, there’s a 20% to 25% price difference in these two versions.

The pricing difference is also because of the high demand for the black fluid film. Although both offer excellent rust protection, people prefer the black one for its aesthetic purposes.

Quantity

Fluid Film is available mainly in two sizes. You will get it mostly in 11.75Oz and 8Oz cans for smaller applications. These two canned versions are popular for most DIY works. However, if you want a larger version for expansive painting and rust-protection facilities, you can even get 1-gallon versions.

Apart from the quantity, both black and regular fluid film has two types, including aerosol spray cans and pails. These two versions will suit different needs. Fluid Film Black is available in similar packaging options, ensuring you can choose the correct quantity for your specific application.

Types of Fluid Film

You must understand that both traditional and black fluid film offers almost identical facilities. However, the actual difference lies in the type of fluid film you choose. It’s available in two types:

- Aerosol spray cans

- Pails

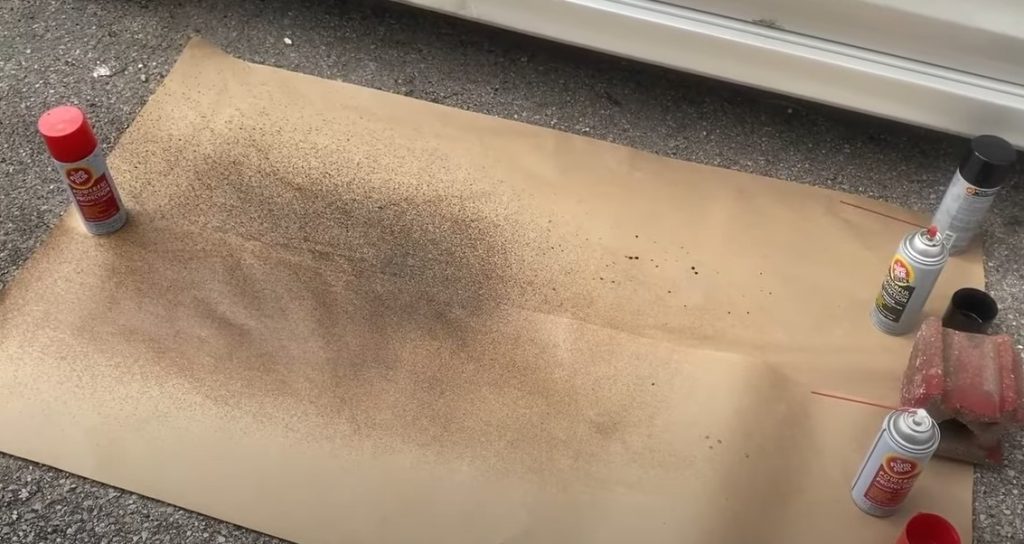

Aerosol Spray Cans

Aerosol cans are convenient for precise and targeted applications. Its convenience and affordability make it a popular choice for smaller tasks. You can just open the spray can and apply it directly to lubricate hinges, locks, or hard-to-reach areas.

You don’t need brushes or rollers to apply the aerosol-based film fluids. Nonetheless, it contains VOC elements that can evaporate after a certain period. So, the volatility and evaporation concern of the aerosol spray cans of the fluid film makes it not so durable.

Pails

Pails of Fluid Film are better suited for larger projects and industrial applications. They are cost-effective when you need a significant quantity of the product. You can apply the pail-based fluid film with a roller or paintbrush. It offers a smoother finish for a brilliant look on any surface.

Also, the pail-based fluid film is primarily free from VOCs. So it won’t evaporate like the aerosol spray cans of fluid film. As a result, it will stick on the metal surface for longer than the spray can version. It makes the pail-based fluid film a worthwhile choice for longevity and a smooth finish.

Different Uses of Fluid Film

Fluid Film is a versatile product with a wide range of applications. From coating the automobile surface to its ship, all airplanes to lubricate and protect the metals from corrosion and rust, its application is limitless. It also brings a beautiful tint to the applied surface.

- Automotive Undercoating: Protects vehicle undercarriages from rust and corrosion.

- Marine Protection: Guards boats and marine equipment against saltwater corrosion.

- Agricultural Equipment: Preserves farm machinery and prevents rust in harsh outdoor conditions.

- Aviation: Used to protect aircraft components from corrosion.

- Industrial Machinery: Provides a protective barrier for various industrial equipment.

- Home Maintenance: Lubricates hinges, locks, and tools.

- Firearms Maintenance: Prevents rust on guns and firearms.

Tips to Use and Apply Fluid Film On Car

When you see the metal parts of your car or the paint getting rusted, it can freak you out. Well, you can confidently apply the fluid film and keep the rust and corrosion at bay. All you need is to use it safely and correctly.

Prepare the Surface:

You shouldn’t apply the fluid film directly to any surface. There can be dust and grease that will prevent the liquid film coating from working appropriately. Also, it won’t stick on the dirty surface and will fall off quickly.

So, you should clean and degrease the surface thoroughly to ensure proper adhesion. You can clean the surface with regular detergent and automobile cleaner. Also, after cleaning the surface, buff it off and let it dry for proper application of the fluid film coating.

Watch this video:

Masking the areas:

You will also need to mask off the areas where you don’t want the fluid film to apply. So, it’s crucial to protect sensitive areas like electrical connections and rubber components. You can use mask tape or even regular ones to cover the exposed areas from fluid film application. It is even more critical if you choose the aerosol spray version.

Apply Evenly:

Use an aerosol spray or a brush to apply Fluid Film evenly. Make sure you coat the surface properly so that it isn’t too thick or thin. Also, you should wear gloves and goggles, mainly if you apply fluid film aerosol spray cans.

Depending on your climate and conditions, reapply Fluid Film annually or as necessary. Ideally, we always recommend applying two coats of the fluid film for the best protection of the surface. You should wait for 4 to 8 hours to apply the second coating. It helps the first coat to dry and cure adequately. If you use it on the outer surface, buff it off for a smoother and glossy finish.

Periodically check for any signs of rust or corrosion and reapply as needed. It will maximize the longevity of the metals without decay.

Last Two Cents

Both Fluid Film and Fluid Film Black offer exceptional protection against rust, corrosion, and moisture. Your choice between the two may depend on the color preference, budget, or specific application needs.

Regardless of which one you choose, Fluid Film can extend the lifespan of your vehicles, equipment, and other valuable assets. It will ensure the surface remains in optimal condition for years. As you apply it appropriately with proper surface preparation and buffing, it will protect the surface sufficiently.