Ported Vs Manifold Vacuum: Why the Vacuum Source Matters

In many older vehicles with carburetors, vacuum pressure plays a crucial role for various reasons. One of these reasons is communicating with the distributor’s advance mechanism, which is necessary for proper timing. Timing needs adjusting so the engine’s spark ignition occurs at the optimal time.

There are two sources of vacuum pressure in these vehicles: ported and manifold vacuum ports, both located in the carburetor. The main difference between the two is affecting the ignition timing. Ported vacuum pressure is low during idle and does not affect ignition timing. Contrarily, the Manifold vacuum affects the ignition timing.

This article provides more information about ported and manifold vacuum ports, explaining how each port functions and its benefits. So, keep reading to learn more.

Ported VS Manifold Vacuum: Quick Facts

Following are quick facts about ported and manifold vacuum pressure.

| Ported Vacuum | Manifold Vacuum |

| Doesn’t affect ignition timing at idle | Affects ignition timing at idle |

| Usually used for the distributor advance mechanism | This vacuum signal is available all the time |

| Its strength is affected by air temperature and throttle position | Its signal strength is affected by load and throttle position |

| Not suitable for accessories in need of a constant vacuum signal | Suitable for accessories that need a constant vacuum signal |

Why Do Vacuum Ports Matter?

Ignition timing is crucial and highly misunderstood in most old-school engines. Without understanding ignition timing, the vehicle performance may remain poor even with tons of extra aftermarket parts.

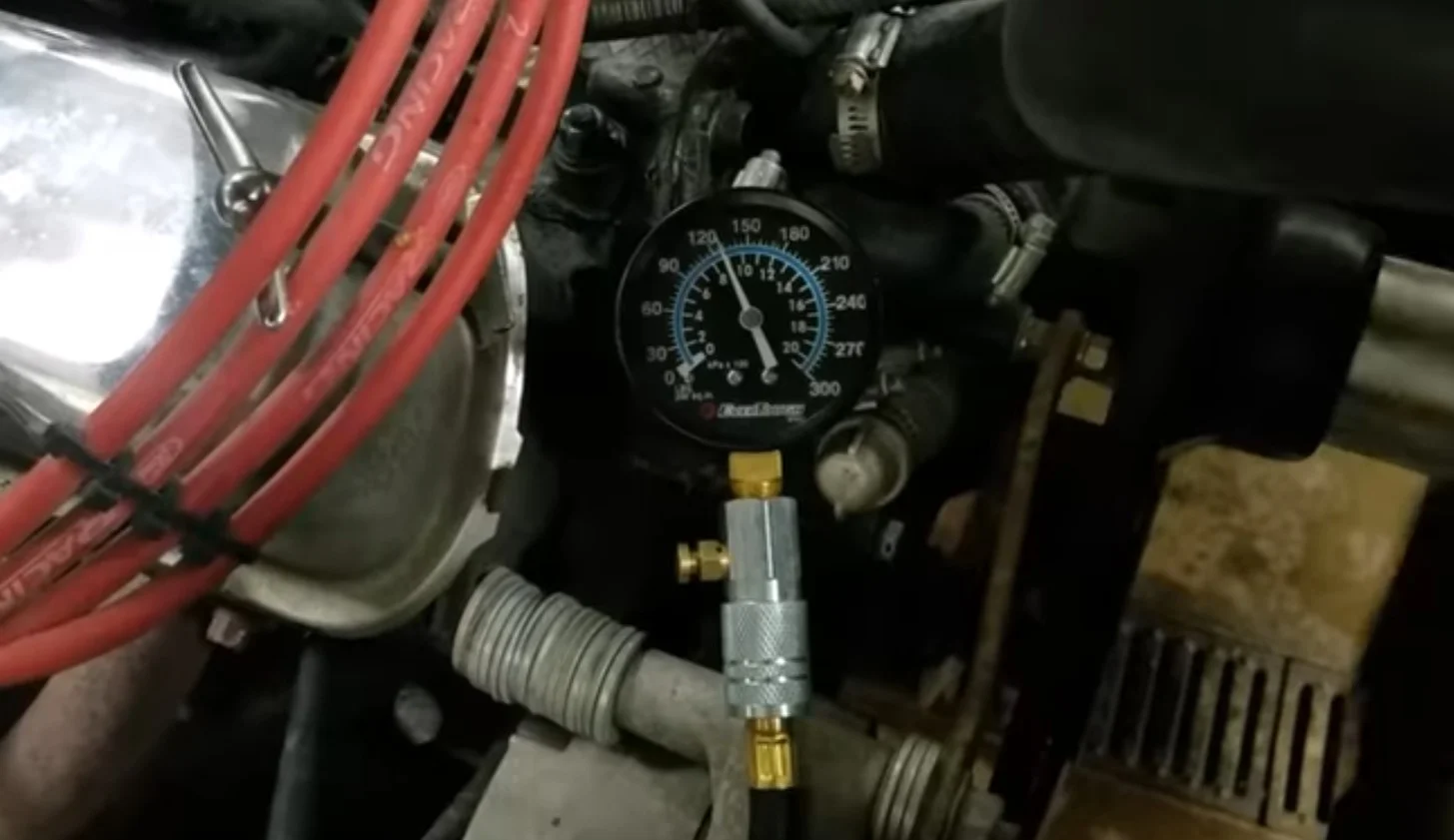

The vacuum port acts as a source of vacuum pressure, needed by a vacuum advance mechanism to adjust the ignition timing accordingly. This mechanism uses the strength of the vacuum signal to adjust, which optimizes the engine performance and helps increase gas mileage.

When the vehicle accelerates when loaded, it requires more fuel in the mixture running rich. More fuel in the engine means quick combustion, and in this case, the distributor adjusts ignition timing late. When idling, the scenario is vice versa, and ignition must begin early.

Ported and manifold are two sources of this vacuum pressure needed by the vacuum advance mechanisms in the distributor. These two ports are on most old-school vehicles on the carburetor.

Most modern vehicles with electronic fuel injection only use manifold vacuum, as advanced timing is achieved electronically. The choice of the port to use as a vacuum source usually depends on the specific engine requirements and the carburetor.

Ported Vacuum

A ported vacuum usually means zero or no vacuum at idle and increases as the vehicle moves or as the throttle opens. The vacuum port on the carburetor is hooked to the vacuum advance canister of the distributor when this port is the source of vacuum pressure.

The ported vacuum port didn’t exist until the late 60s. It was an attempt by manufacturers to improve emissions and meet emissions laws. The idea was to have little or no spark when a vehicle idles, increasing exhaust temperature, burning carbons, and improving emissions.

Advantages of Using Ported Vacuum

There are several advantages associated with using the ported vacuum pressure. They include.

- Improved Fuel Economy

Using a ported vacuum can help improve fuel economy by advancing ignition timing. The vacuum advance mechanism is usually connected to this port, controlling ignition timing.

This system allows the engine to produce more power when the vehicle is at low speeds, using the same amount of fuel.

- Effective for Street Engines

Ported vacuum pressure works better for street engines with stock and mild cams. These engines do not usually require ignition timing when idling, as the camshafts make enough cylinder pressure at idle.

For the carburetor to idle at ideal rpm, you may need to adjust your throttle too much if the vacuum pressure source is the manifold port. Also, the initial mechanical advance may need to be too little, which can cause the engine to respond lazily.

However, add several degrees on the initial mechanical timing to use ported pressure on the carburetor. The following video explains the ideal mechanical timing that may work on your engine

Manifold Vacuum

Manifold vacuum pressure is the air pressure difference between the intake manifold of the vehicle’s engine and the atmosphere. The engine’s piston movements during the intake stroke cause the manifold vacuum pressure.

The manifold vacuum pressure is usually strong when the vehicle idles or cruises at low speed. The vacuum pressure is strong since it’s directly connected to the intake manifold of the vehicle’s engine, where the downward movement of the piston creates pressure.

Advantages of Using Manifold Vacuum

The following are some advantages of using a manifold vacuum

- Helps Vehicle Cruise and Idle Better

As mentioned above, using a manifold vacuum affects ignition timing at idle and when the vehicle cruises. The manifold is only cracked slightly when the vehicle cruises, as it only requires a little rpm to run.

During this time, there’s a strong vacuum from the engine exerting a pulling force on the diaphragm in the vacuum advance. Vacuum advance links to advance timing which in turn adjusts accordingly. The result is that the vehicle idles or cruises way better and remains cool.

- Provides constant Vacuum

Various vehicle systems and accessories require a constant supply of vacuum pressure. These systems and accessories include power brakes, HVAC control, and emission control systems, including positive crankcase ventilation (PCV).

While using the manifold vacuum pressure, these systems get a steady supply and remain effective.

- Emission Control

The vehicle monitors and manages emissions since emission control systems remain active even through idle. Also, with the manifold vacuum pressure, various parts that require a constant vacuum supply don’t overload the engine, improving fuel use and reducing emissions.

Which Port Should I Route Vacuum Canister?

Both ports can be effective as a source of vacuum pressure for the vacuum canister. They all depend on how well you adjust the vacuum advance and to avoid pinging while the vehicle is on the throttle.

Manifold Vacuum

The vacuum advance should be at least 10 degrees when on the manifold vacuum port. Also, the initial mechanical advance when the vehicle idles also needs adjusting to at least 14 degrees. The vacuum advance should be unplugged when adjusting the mechanical advance.

However, the number of degrees you set may vary with the engine type. For instance, some small block Chevys work better with a total timing of about 34 degrees when running at 3000 rpm.

Ported Vacuum

The ported vacuum pressure is necessary when the engine has a large camshaft that affects the vacuum pressure at idle. You need to use the ported vacuum port for the canister if your manifold vacuum pressure cannot hold a steady vacuum when idling.

However, some vacuum advance canisters are adjustable. In this case, you can adjust it to steady the pressure. You can still use the manifold vacuum port if your canister is adjustable, and there is no need to switch to the ported vacuum port.

Also Read:

Deep Creep Vs PB Blaster: Which One Should I Use?

Outro

The decision of whether to utilize the ported or manifold vacuum port as a vacuum source has been a topic of extensive discussion. Both ports are excellent sources of vacuum pressure from the carburetor, which is necessary for various vehicle functions, including connecting the vacuum canister.

Nevertheless, either port can function with adjustments to the initial mechanical advance to guarantee optimal engine performance. If you’re uncertain which vacuum port to use, seek advice from a reliable mechanic.